Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

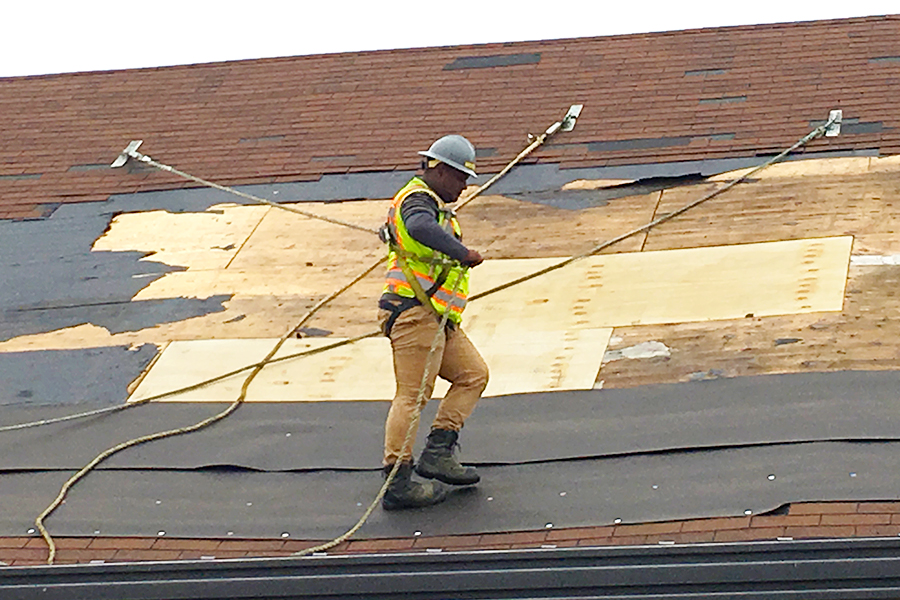

Hill Air Force Base SABER: $270,000,000

This newly awarded SABER Contract at Hill AFB in Utah was awarded to our Joint Venture Company Kekolu-Rio Vista Joint Venture. Under this SABER we furnish all management, supervision, labor, materials, equipment and incidentals required for a broad range of maintenance, repair and minor construction work on various real property facilities at installations covered by the contract. This contract also includes design and engineering services. Task orders range in size between $25,000 and $1,500,000 and will include disciplines that include, but are not limited to: demolition, carpentry, plumbing, electrical, mechanical, painting, welding, pipe fitting, sheet metal, roofing, site work, site utilities, excavation, landscaping, concrete, masonry, pavements, fencing, asbestos and lead base paint abatement, Intrusion Detection Systems (IDS) design and installation, Access Control Systems (ACS) design and installation, fire alarm design and installation, fire suppression design and installation, communication networks and systems, Video TeleConference (VTC) and Secure Video-Conference (SVTC) system design and installation and systems furniture removal, repair and installation.